ALITFLOCK 4840 is an adjuvant in the filtration process of paint stripping baths, as it greatly improves filter presses’ efficiency and productivity when treating exhausted, contaminated baths.

Such efficient filtration is often a key factor to make paint stripping a cost-effective process. During a cycle, paint is removed from workpieces and progressively accumulated in the paint stripping bath. The higher the amount of paint sludge dissolved in the bath, the greater the problems, because it translates into longer cycle times and more expensive processes.

Higher volumes of sludge also mean that the liquid is more viscous: this can pose a risk of tank heating and liquid dragging, which again translates into greater costs.

An increased amount of paint sludge can also generate a crust that may clog the hydraulic circuit, pumps, and pipes, thus calling for higher maintenance costs. It is therefore clear that the regular and efficient filtration of a paint stripping bath is crucial for cost effectiveness.

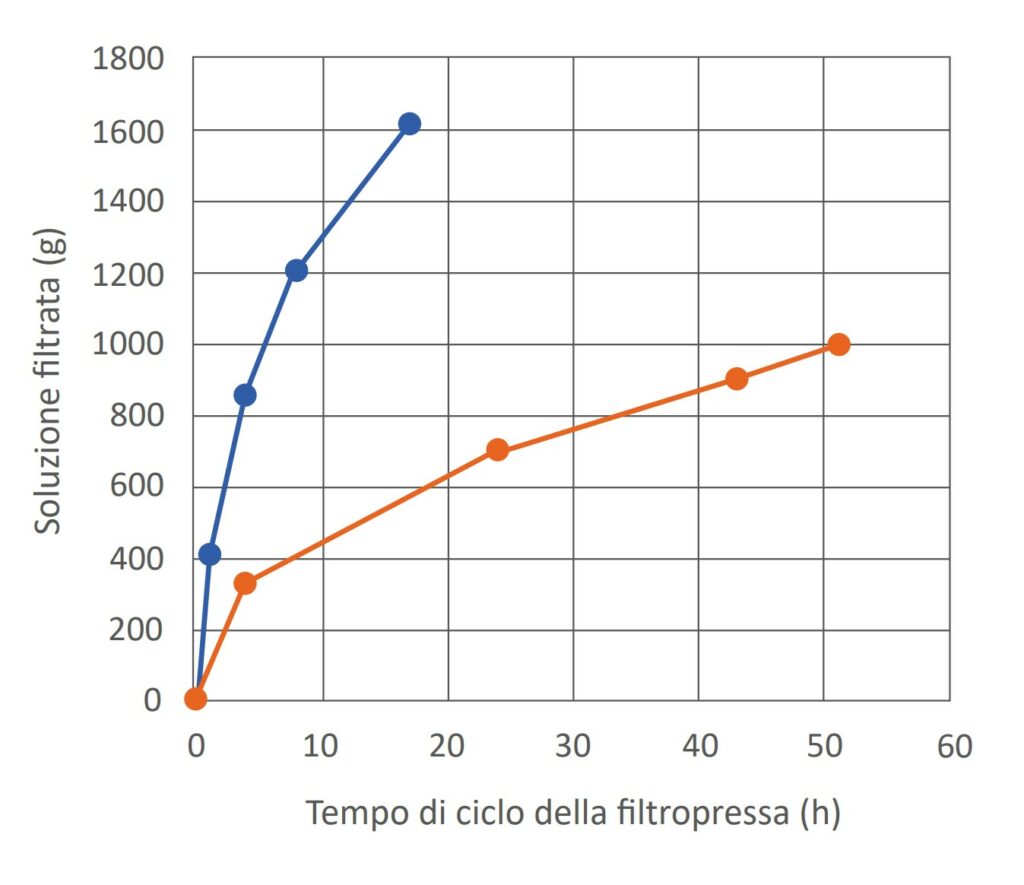

FILTRATION TEST WITH FILTER PRESS

With 15% AlitFlock 4840

In 18h more than 1600g of filtered solution

Whitout AlitFlock 4840

More than 50h less than 1000g of filtered solution

A: With 15% AlitFlock 4840

B: Without AlitFlock 4840

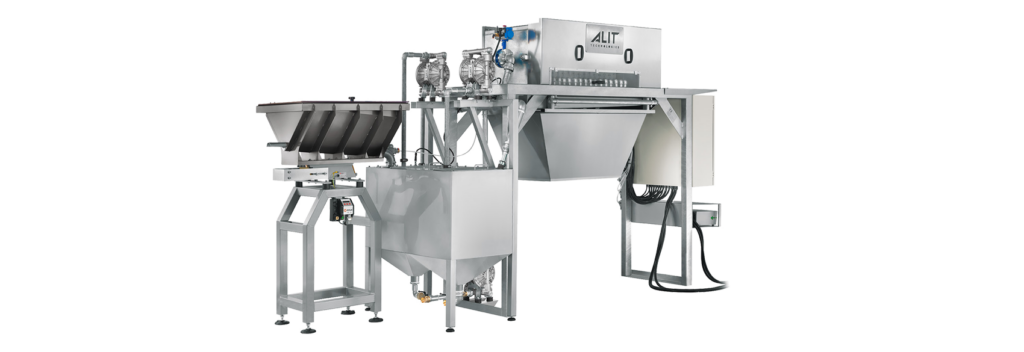

FLOCCULANT DOSING DISPENSER WITH A VIBRATORY CHANNEL

ALIT Technologies‘ flocculant dosing dispensers have been specially designed and sized for the automatic addition of flocculant to tanks containing paint stripping sludge.

We offer different sizes of dispensers depending on the type of paint stripping equipment. By means of a special vibratory channel, they enable an ALITFLOCK series flocculant to be reliably transferred from the vibrating hopper to the sludge sedimentation tank, where it is mixed

by the pneumatic mixer. The dosing dispenser’s hopper is equipped with a level sensor that signals when the minimum product level has been reached. It is possible to adjust the automatic dosing parameters by operating directly on the filter press’ panel interface.

ALIT Technologies‘ FASTRIP FP filtration systems are the perfect response to this need. They feature a filter press that separates the paint sludge from the paint stripping solution, so that the filtered, purified solution can be recirculated to the stripping tank.

The solid waste, on the other hand, is pressed into sludge cakes that are collected and disposed of separately.

The paint sludge extraction rate, i.e. the kilograms of sludge removed from the bath per day, and the quality of the filtered liquid sent back to the stripping tank are two key factors in maintaining the paint stripping bath’s best performance level.

ALITFLOCK 4840 handles them both, because it improves both the paint sludge removal rate and the quality of the filtered paint stripper.

ALIT TECHNOLOGIES SpA - Via Cavalieri d'Italia, 7 - 37047 SAN BONIFACIO (VR) ITALY - VAT IT03341620247 | Company Details - Privacy Policy - Credits